Panjiva Research held a two-part event on Feb. 10 themed “Past Tense, Future Imperfect – Outlook for Supply Chains in 2021” where we investigated the outlook for trade policy, the congested logistics sector and supply chain restructuring. Replays of the panels on trade policy and on logistics are now available. This report provides precis of the event along with data insights.

The first panel, including Satyam Panday of S&P Global Ratings, Rochelle March of S&P Global ESG and Chris Rogers of S&P Global Panjiva, looked at the prospects for trade policy in both the U.S. and globally. The second panel, including Will Urban of Flexport, George Griffiths of S&P Global Platts and Eric Oak of S&P Global Panjiva, looked at the prospects for the logistics industry and supply chain adaptations in the coming months.

Q: Will the Biden administration toss the phase 1 trade deal in the rubbish and start over, or try and amend the existing deal?

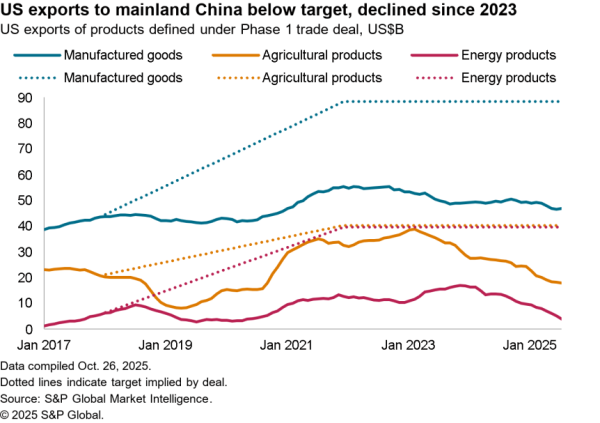

The Biden administration has acted rapidly on the political elements of its plans but the trade related elements will take longer. In particular President Biden wants to build up international alliances rather than acting unilaterally. China is a strategic competitor but it has delivered much of what was committed under the phase 1 trade deal in terms of changes in rules on intellectual property, foreign investment and its commitments to purchase U.S. goods in the last three months of 2020, as discussed in Panjiva’s research of Feb. 8.

There’s also a risk that withdrawing from the phase 1 trade deal would lead China to redirect its purchases particularly of energy where U.S. exports to China reached $9.74 billion in 2020, Panjiva’s data shows, led by exports of crude oil which reached $6.76 billion from $2.96 billion in 2019 while shipments of LNG rose to $1.30 billion from $62 million.

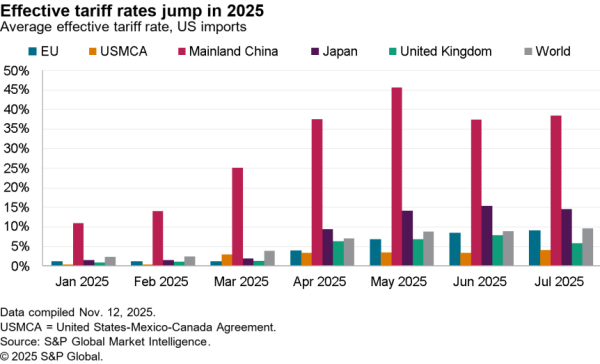

Looking more broadly the administration is unlikely to roll-back tariffs immediately, though some of the tariff programs – for example in steel and those related to aerospace – may be rolled back for allies. President Biden is not a free-trader through-and-through though and may be willing to continue to use trade restricting measures to support America’s workers and the nation’s geopolitical objectives.

Source: Panjiva

Q: Where will the burden of the cost of the Biden administration’s environmental policies fall?

There will inevitably be winners and losers as the Biden administration puts its environmental policies into play, but what is certain is that they will be more costly to deliver in the future if they are delayed today. It’s important for the administration to get ahead of the curve by creating a social safety net and providing a jobs training program for the environmental transition.

The right types of incentives are needed as well. Arguably carbon taxes, of which there are as much as $529 billion on the table already, are the simplest and most elegant way of pricing in the externality.

Different sectors of the economy will also be able to handle the additional costs in a very different way. In the automotive sector a tax on fossil fuels is needed, and will raise costs for consumers, but there are technologies that are already available to mitigate emissions though they come with their own supply chain issues. Aviation is more complex with a lot of technological investments needed to transition to biofuels or other routes. Shipping and freight meanwhile have easily available technologies ranging from biofuels to wind and could look to sell credits to aviation.

Q: Is there any evidence of onshoring to the U.S. actually taking place?

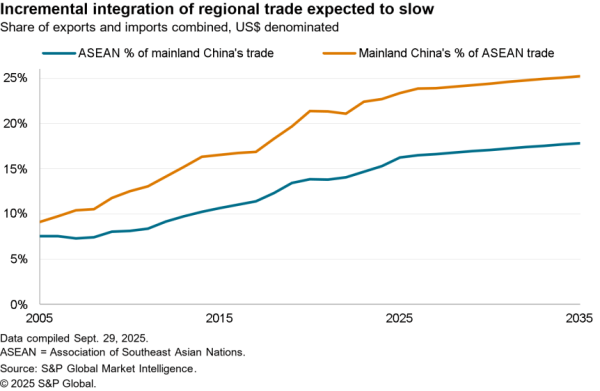

Thus far there are few signs of the impact of onshoring at the macroeconomic level, though individual supply chains have shifted in response to tariffs. More often than not though there has simply been a shift to other offshore centers of production and away from, say, China in response to the Trump administration’s tariffs.

Taking disc drives and an example (under HS 8471.70.40) imports from China have fallen by 90.8% in 2020 versus 2017, Panjiva’s data shows. Yet, imports from Thailand climbed 34.4% higher and those from the Philippines rose by 38.2% with the result that total imports increased by 5.3% over the same period.

More serious consideration does need to be given, however, to whether supply chains need to shift to a just-in-case basis rather than just-in-time or lowest cost in the wake of the disruptions caused by the pandemic. Such moves would require a cohesive set of government policies to deliver, which many countries other than the U.S. have already started to implement.

Source: Panjiva

Q: Logistics networks have been heavily congested in Q4 and in January, what has caused that? What’s needed to clear the congestion and how long might it take to get back to normal?

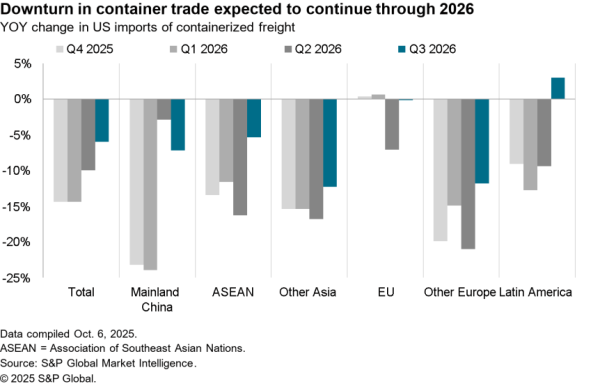

The sectors experiencing the fastest rate of growth in shipments have been home goods and electronics as people are at home instead of making discretionary purchases outside of the home. There’s been a shortage of both ocean and air freight capacity though more recently the challenges have lane much more on the ocean side. The congestion that was first seen in the west coast of the U.S. is now spreading.

Importantly there hasn’t been a slowdown in the peak season. Indeed, many Chinese factories are staying open as a large proportion of their staff are not going home for lunar new year. As a result there may not be much of a traffic slowdown in the period after lunar new year so these conditions could last until April or even May time.

While time will heal, inasmuch as vaccines may lead to fewer lockdowns and more non-goods spending, it’s possible that shipping rates could end the year below their current levels but still well above those seen historically as additional costs and risks are priced in.

Source: Panjiva

Q: What are the prospects for the automotive sector? Is reshoring an option to reduce exposure to congested logistics networks?

The operation of just-in-time supply chains across the board, not just in the automotive industry, can require the widespread use of airfreight. That’s simply not been available during the pandemic when air traffic has been reduced. The use of premium ocean services should provide an alternative but there are capacity issues there too. More recently the sector has had bigger problems from the availability of components than the availability of shipping capacity or rates.

Reshoring is certainly an option and the rebuilding process following the pandemic comes alongside tariffs in being a factor that has accelerated existing trends towards balancing lower labor costs with responsiveness and time to market. It’s important to note though that even with contract manufacturing supply chains can’t be reset overnight. It can take years to identify suppliers, tool up, test and implement new products as part of an existing supply chain.

Q: Are we seeing an acceleration in construction and delivery of more empty containers?

The normal production of ocean containers ground to a halt during the first half of 2020. There’s normally growth of 6-8% of the container fleet built each year on top of replacements so there’s a structural lack of capacity right now. That’s come on top of a reduced availability of staff at ports who have been sidelined during the pandemic. Put together there’s as much of a supply crunch currently as a demand overflow.

Q: Is the push to decarbonization of the economy going to have an impact on shipping costs?

The final rules for the shipping industry are a long way from being set, but we are already seeing container lines pursue biofuel strategies as well as longer-term, hybrid fuelling strategies. The investments will take decades and cost billions of dollars. The desulfurization process is instructional in that there were a lot of concerns about the impact on the shipping industry but it appears in hindsight that costs were passed through to users of shipping services.

Q: The congestion on the west coast of the U.S. is well-documented, will we see something similar on the U.S. east coast and in Europe?

It’s likely that we’ll see congestion build up on the U.S. east coast as has been the case in the northwest in the wake of diversions away from the congested southern Californian ports. Panjiva’s data shows the wave of traffic expansion spreading with imports to Seattle / Tacoma having grown by 26.8% year over year in January from 10.7% in November. Shipments to Mobile and Miami reached 42.3% from 5.0% and 29.3% from 0.1% respectively over the same time frame. Imports to New York have already been expanding rapidly with growth of 26.7% in January.

We’re also seeing similar issues in the EU as well as the U.S. Ports in the United Kingdom have been particularly beset by soaring rates which reached $10,000 per FEU on Jan. 1 compared to $1,500 on Aug. 31. Similar demand trends to those seen in the U.S. have occurred, with the added complication of stockpiling ahead of the move to new trading arrangements with the EU.

Source: Panjiva