General Motors is still planning to roll out a range of new electric vehicles under its Hummer and Cadillac brands in late 2021 despite the COVID-19 pandemic’s impact on operations, finances and sales, Wards Auto reports, with U.S.-based assembly.

In the short-term there should be a resumption of EV manufacturing in the U.S. after Tesla committed to reopening its factory despite regional lockdown requirements, according to CNN. Tesla may also be close to announcing a new battery system with a new “million mile” life, Reuters reports.

Both face a depressed sales market, as outlined in Panjiva’s research of May 14, as well as potential regulatory disruptions from the roll-out of the U.S.-Mexico-Canada Agreement from July 1.

In the meantime, sourcing for U.S. electric vehicle manufacturing had been in decline. A 34.3% year over year slide in electric vehicle battery imports in March, Panjiva’s data shows, was in part explained by the start up of Tesla’s gigafactory for batteries as well as a shift in manufacturing of vehicles to China.

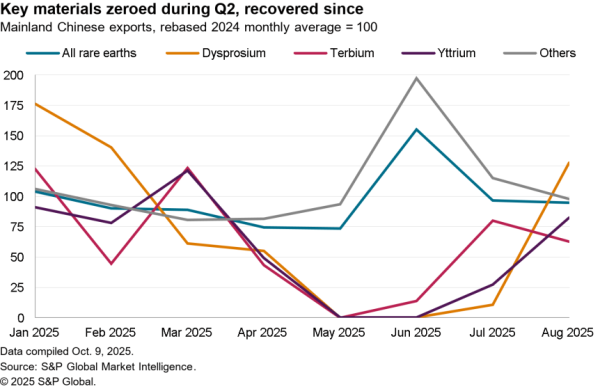

Yet, there was also a downturn in imports of raw materials. Imports of lithium fell fastest with a 30.3% drop while cobalt and rare earth materials (including magnets) dropped by 16.9% and 18.0%.

Source: Panjiva

That decline likely continued in April, with total U.S. seaborne imports of the four product classes having dropped by 9.5% year over year. Among the battery suppliers there was a 4.5% dip in shipments linked to Panasonic, linked in part to the downshift in imports for Tesla. By contrast shipments linked to LG Chem jumped 433% higher as it starts to set up production with General Motors.

Suppliers of rare earth magnets appear to be having a tougher time. That may be a truer sign of underlying vehicle production given their importance in motors for vehicles and relatively unchanged supply lines. Shipments linked to Hitachi have declined by 37.5% while Shin Etsu’s fell by 22.2%.

Source: Panjiva