The fourth quarter of 2021 will likely look different than the holiday seasons in previous years. This is largely due to the ongoing high-water mark of imports flowing into the U.S. since March. Imports in March were the highest recorded, an unlikely time for volumes that normally peak in October. The levels reached in March, May and August of just over 3 million TEUs, combined with freight rates and traffic outside of Los Angeles and Long Beach, suggest that imports are near their maximum monthly capacity. This is greater than what was seen in the 2020 peak last October, 2.9 million TEU, but any company that has not adapted may get stuck in congestion.

Source: Panjiva

Carriers reap the benefits of high demand

With demand for freight services outstripping supply, shipping rates have increased rapidly. The average price of container shipping out of China has increased by 95.1% since Dec. 31 and continues to grow, increasing by 10.4% since the end of July and 2.5% in the week to Sept. 24. Rates to the U.S. West Coast have increased slower than the average, up 83.0% since Dec. 31, but increased by 15.3% since the end of July. On the other hand, imports to Europe have increased faster, up 134.0% since Dec 31. These differences in regional pricing may reflect the relatively large capacity of the U.S. west coast, as well as the potential of acute events like the Suez blockage increasing spot rates.

Source: Panjiva

High rates and high demand are great for logistics companies, who are likely as excited as retailers for a big holiday season. Carriers that stand the most to gain are ones who ship a greater proportion of goods in October, traditionally the peak month, rather than those that balance shipments across the year. A high proportion of shipments in October would indicate an ability to burst capacity, adding services when needed and backing off during the parts of the year that are usually slow. The 2M Alliance seems to be the best at this with members MSC and ZIM importing 11.9% and 12.0% in October 2020, greater than the 11.0% baseline of October 2020 imports. These proportions were likely boosted by the shipping slowdown during the pandemic, but are equal to the next closest carrier, HMM, with 11.9% of 2020 imports in October. One outlier was unaffiliated liner SM Line, which had the highest proportion of October imports in 2019, 10.2%, but fell to 9.5% in 2020. This may indicate that the firm was impacted more than most by the pandemic, recovering slower for the 2020 peak season.

Source: Panjiva

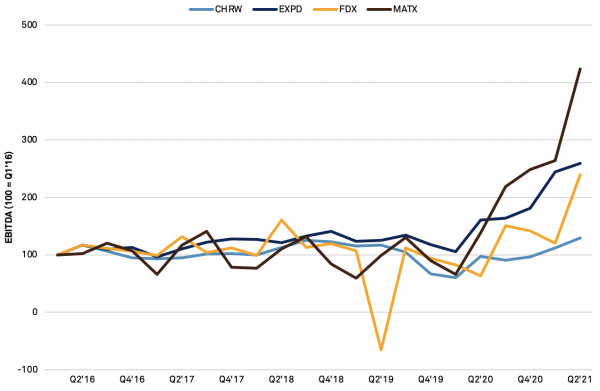

This has led to increased profits for logistics companies, with forwarders like CH Robinson and Expeditors reporting EBITDA growth of 32.4% and 61.7% year over year respectively. FedEx’s EBITDA increased by 276.2% year over year, while liner Matson saw the same metric grow by 205.6%. During the company’s Q2’21 earnings call, Matson CEO Matthew Cox said that “the supply chain and supply-demand conditions to remain in place and lead to a high level of demand at least into Lunar New Year.” This optimism is likely a large part of the growth in investment in new ships, ports, and services as discussed in research of Aug. 25. High shipping rates will likely keep profits high in Q4 as holiday demand ramps up.

Source: Panjiva

Firms react to a new normal

Corporations will likely have different reactions to the high costs, congestion, and uncertainty that the pandemic and subsequent recovery have added to supply chains. One way that firms can address these concerns is through inventory strategy. Throughout much of the past decade, companies have focused on reducing inventories through strategies like just-in-time (JIT) sourcing. This allows working capital efficiencies that can boost the performance of the business.

The risk, however, was seen during the pandemic as companies without suitable inventory reserves were more likely to have to pause manufacturing operations or other services. Stock-outs for retailers are also unwanted outcomes that can damage consumer reputation. Data comparing revenue to inventory levels across several industry groups shows that companies in the retail and household products areas saw decreased ratios, falling 12.6% and 5.8% year over year respectively. This indicates higher inventories for each dollar of revenue. Other industry groups like materials and autos are operating leaner for each dollar of revenue, also likely reflects high demand for desired products. The revenue over inventory ratio for autos increased by 35.5%, semiconductors by 30.2%, and materials by 23.1%. These sectors have seen strong demand, with semiconductor shortages and rising material costs making news.

Source: Panjiva

High demand is likely to lead to inflation, and this is on the minds of executives speaking in earnings and guidance calls. Mentions of inflation increased by 74.0% in calls made in the Q3, increasing from 59.6% year over year in Q2. This is likely to continue to be a hot topic in Q4, especially if macroeconomic conditions remain unchanged. Logistics and sourcing topics also continued to build, increasing by 14.0% and 18.9% year over year in Q3. Other topics include climate related topics which have been increasing steadily as well, up 118.5% year over year in Q3, likely in response to proposed regulations like the EU’s fit for 55 program, while mentions of tariffs continued to fall, out of fashion since the cooling of the U.S. China trade war.

Source: Panjiva

The talk about inflation is not unfounded as inflation, starting in raw materials, has worked its way through supply chains to intermediate products. The producer price index for chemicals, plastics, and base metals have increased by 0.7%, 0.9%, and 1.6% from July to August. Goods further down the chain also saw increases start to creep in — apparel saw prices increase by 0.3% and furniture saw a 0.1% month-on-month increase. Different supply chains interact with inflation at different speeds as companies pass costs to their customers and oppose price increases from their suppliers. This may hit consumers sooner if companies think their markets can bear higher prices during the upcoming holiday season.

Source: Panjiva

Panjiva data can show which sub-industries are ahead of last year’s holiday season imports. Footwear companies are seeing the largest increase in imports in July and August, up 278.0% after Q2 imports increased by 39.3% year over year. Footwear companies may be more flexible than most as labor is still a major cost component in that industry. For example, Steve Madden CEO Edward Rosenfeld noted in August that they had “moved about half of the Steve Madden Women’s production to Mexico and Brazil for fall” out of China. This is also likely a sign of early stock-up, companies shipping earlier in anticipation of delays and congestion in logistics.

Apparel retailers like TJX may be facing more headwinds, however, with imports in July and August increasing by 42.6% year over year after a 138.3% increase in Q2. TJX executives said in August that they expected “freight, supply chain and wage costs to be higher” in the future. This could be due to pandemic-related pressure in Vietnam and other Southeast Asian countries as those nations work against a resurgence of the virus. General merchandise stores may be the most at risk of a disappointing holiday season, with imports associated with those firms decreasing by 53.2% year over year in Q2 and 79.3% year over year in July and August. This may be the continued challenges that BJ’s Wholesale CEO Robert Eddy mentioned during the company’s earnings call in August, when he said they “expect supply chain and sourcing challenges to continue for the foreseeable future.” The diverse stock of these stores may make sourcing for these firms more difficult, and they may not be able to prioritize a certain route or product category.

Source: Panjiva