This report takes two approaches to analyzing the fallout from the SARS-CoV-2 / COVID-19 coronavirus outbreak on global trade and corporate supply chains. The first draws on over 50 reports from Panjiva Research to identify 11 themes emerging on an event-driven basis. The second takes a more programmatic approach to combining stock price performance and supply chain characteristics to identify seven examples of differentiated corporate performance. All Panjiva’s research on the topic can be found on our dedicated microsite.

11 lessons from the outbreak so far

Since news regarding the outbreak of SARS-CoV-2 / COVID-19 coronavirus in Hubei province, China in mid-January Panjiva research has published over 50 short-form reports looking at the issue across a wide range of industries. We’ve identified 11 themes emerging from our analysis so far:

The drag to supply chains has been widespread

Early disruptions were felt in the automotive sector with Fiat-Chrysler, Toyota, Nissan and Tata and others having to cut production. The autos sector is more exposed than many due to the lengthy, just-in-time nature of corporate supply chains. The concurrent rise in “ force majeure” support from the Chinese government – effectively indemnifying suppliers from the consequences of shutdowns – will reduce the ability of buyers to offset higher costs or lost profits.

The electronics industry was also identified early as a problem area in part due to the length of supply chains and importance of the industry in the initial outbreak region of Hubei province including Hon Hai and China Electronics Corp. Nintendo was one of the first firms importing from outside that region to report problems, though the challenge related more to peripherals than consoles.

Companies in the capital goods sector rapidly recognized the challenge and baked lost production into their earnings guidance. One example was Illinois Tool Works which included one week of lost production, relying on China for 46.6% of imports in 2019 Panjiva’s analysis of seaborne import data shows. Another is JCB which has had to cut production in the UK due to parts shortage. Even though China represents just 3.8% of British intermediate capital goods imports one part can be enough to stop factory operations.

Sales in China have been disrupted as much as purchases from China. Exports of commodities from Brazil including soybeans and iron ore were already in decline before the shock. Similarly, Mexican steel output has started to decline and had already fallen by 8.4% year over year in January. Apparel firms including Adidas, Puma and Under Armour also warned of lost sales in China as well as facing downstream challenges to supply chains in U.S. and Europe.

Source: Panjiva

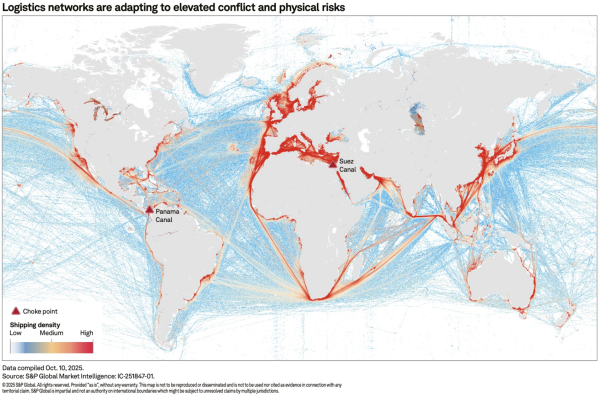

Logistics has slowed down rapidly

The slowdown in Chinese exports has taken time to be appear in trade data given shipping times involved and latency of data. Yet, we’ve already started to see a decline in seaborne shipments to the U.S. west coast while U.S. total imports in total fell 7.5% year over year in February including a 21.0% drop in shipments from China. Air freight rates have also surged, exacerbated by a loss of belly-cargo capacity in passenger jets.

Container-line Matson warned that there’s been a drag in the form of reduced port activity, closed forwarding operations as well as reduced shipping volumes. Maersk has also cited “significantly lowered visibility” but expects a “strong rebound” – more on which below

From a technical perspective there are also challenges caused by a lack of empty containers in the U.S. to allow for exports back to China. That’s been seen in the grains sector where DDGS exports already fell 16.5% year over year in Q4.

Source: Panjiva

Many firms don’t yet know the impact

Our review of over 6,000 company conference calls from Jan. 20 to March 4 shows 42.3% of firms mentioned coronavirus, with a peak in the chemicals sector with 77.1% of firms alongside autos and tech hardware at 72.4% and 69.3% respectively. The latter two are not a surprise, the preoccupation in chemicals may reflect the specificity of products and business-to-business nature of the industry.

Broadly, U.S. corporations expect a significant slowdown in activity. The latest ISM survey had an import expectation reading of 42.6 (below 50 indicates a decline) which was the lowest since at least 2010 – a respondent in the electronics industry noted there’s been a “mad dash to dual source”.

Source: Panjiva

Tariff lessons come in useful

Apparel retailer Stitch-Fix has been typical in having already restructured its supply chain away from China in response to U.S. tariffs – Panjiva’s analysis shows China represented 4.7% of U.S. seaborne imports linked to the firm in 2019 from 13.2% in 2018. Yet, its increased reliance on the rest of Asia means it is not out of the woods yet.

Lego’s in-market, for-market approach has cut its exposure to globalized supply chain risks, though it will still lose sales in Asia. U.S. retailer Target meanwhile has “made some slight adjustments” in response to coronavirus and has already cut its imports from China to 85.2% of total U.S. seaborne imports linked to the firm in 2019 from 95.8% in 2020.

Other firms may further accelerate existing plans as they already did for tariffs, with Google, Microsoft and Hon Hai all following that pattern. Lenovo is another example having cut its reliance on China to 65.4% of U.S. seaborne imports total in 2019 from 80.1% in 2016, shifting in the short term to Mexico and India instead of China.

Source: Panjiva

Expedited deliveries becoming more important

Where supply chain switching isn’t possible there’s been a move to expedited deliveries via air to bootstrap supply chains as soon as factories reopen. Indeed, the Indian government has committed to supporting airfreight costs to maintain the electronics industry – China represented 42.7% of Indian electrical and electronics imports in the 12 months to Nov. 30.

At the corporate level, Deere & Co. allocated $40 million in the current quarter for expedited freight even though just 8.5% of its supplies by sea to the U.S. came from China. Magna International meanwhile has flagged that the decision to expedite deliveries is up to its customers. It has nonetheless also been reducing its shipments from China to the U.S. in favor of those from Mexico – China represented 47.0% of its U.S. imports in Q4 while Mexico accounted for 23.6%.

Source: Panjiva

Second order effects are beginning to be felt

Firms are facing both direct and indirect challenges to their supply chains. At a high level the Cambodian government has warned about a second-order effect for customers of Cambodian factories resulting from fabric shortages from China. Levi Strauss and Adidas have rapidly increased their imports to the U.S. from Cambodia recently – while their sourcing of completed goods is diversified they may not be so in fabrics.

Fast Retailing has already seen a slip in shipments of at least two weeks despite aggressively moving its sourcing to Vietnam from China.

There’s also been surprising downstream impacts. Housebuilder Toll has warned that a shortage of lighting – where seaborne imports fell 13.6% year over year in the first three weeks of February – is reducing its ability to complete homes.

Source: Panjiva

Retailers winning on sales, may lose in supplies

Retailers of health and personal care products are unsurprisingly doing well. There’s a limit to the gains though given availability constraints. Costco has stated it has started to look for “other sources where possible” which could take a few weeks to resolve – there was already a 31.3% year over year drop in imports from China linked to the firm in February.

U.S. imports of soap and hand sanitizers had previously been in a decline with a 30.9% year over year drop in imports from Germany and an 18.7% slide in shipments from China in the three months to Jan. 31. Not all importers have seen a decline though, with a recent surge in shipments linked to Procter & Gamble and Johnson & Johnson.

Source: Panjiva

Healthcare drawbridges drawn up

The governments of Turkey, India and others have reduced exports of healthcare products. That will increase the reliance on still freely available resources, e.g. Mexico in case of the US, but again there is only finite supply on a short term basis.

The potential for increased costs has led the U.S. government to remove tariffs on medical supply imports from China. The exemptions cover 10 products where imports from China were worth $3.68 billion in 2019. That may help imports associated with Cardinal Health and Brady Corp who rely on China for 59.4% and 31.6% respectively of their U.S. seaborne imports.

Source: Panjiva

Earlier shortages will reverberate for weeks or months

The port of Baltimore is cutting two days of activity in response to reduced shipping that is already known about. There have been similar warnings from New York, Los Angeles and the American Association of Port Authorities. The latter has warned the drop in shipping could be 20% compared to 2019 in Q1.

Similarly there are forthcoming disruptions into Mexico according to Kansas City Southern, with the automotive sector a particular concern – General Motors accounted for 23.7% of shipments into the port of Lazaro Cardenas in 2019.

Hapag-Lloyd meanwhile has indicated there will only be an “extended period or recovery” – Panjiva’s data shows that imports from Ningbo and Yantian ports to the U.S. handled by Hapag-Lloyd fell by 29.4% and 20.3% respectively in January and February combined.

Source: Panjiva

It’s starting to get better, in places

There’s already been a reopening of Chinese business and ports with evidence from freight forwarders including K+N, DP-DHL, UPS and CMA-CGM citing the move into a recovery phase. That’s particularly important for UPS and CMA-CGM whose U.S. seaborne businesses are particularly exposed to China at 61.5% and 48.7% if inbound shipping respectively.

Outside logistics, toymaker Mattel has flagged that factories have reopened but are still scaling up while Hasbro is still “working to mitigate the impact”. The industry is particularly exposed given China accounted for 84.0% of U.S. toy imports in 2019, though at least the disruptions are occurring outside the peak season.

Source: Panjiva

Post coronavirus bounce back could mark a return to same old problems

While it is too early to discern “post-coronavirus” conditions, there may be a hangover for global trade policy. Chinese steel exports look set to surge – for example shipments by Baosteel to the U.S. already surged 44.0% year over year in January and February combined – which could lead to a new round of U.S. tariffs.

Similarly China may miss its commitments to increase purchasing from the U.S. as part of the phase 1 trade deal – indeed imports of products covered by the commitments were 59.0% lower than they should be in January. So far there’s no sign of either side wanting or granting leniency, while the recent crash in energy prices also pitches a curveball.

Source: Panjiva

Explaining differential sector performances

The following analysis considers the proportion of each companies’ supply chain in the U.S. drawn from Asia and the proportion of revenues from Asia in comparison to sector-relative stock-price performance between Jan. 1, 2020 and March 6, 2020. The supply chain measure is calculated as the TEUs (20-foot equivalent unit) of containerized freight imports from Asia per dollar of cost of goods sold in the most recently reported full year. The revenue measure is based on companies’ self-reported data and as such has a lower level of completeness.

The examples drawn below have been selected qualitatively from the results of the quantitative analysis to provide a series of in-sector comparisons. In this context, returns indicate a company over or under performing the mean of their sector. See the appendix for more information on the methodology, including source code for drawing the data from S&P Global’s XpressFeed product.

Source: Panjiva

Retail apparel – Vera Bradley vs Ralph Lauren

Asian revenue exposure seems to matter less than supply chain exposure in the retail sector. Ralph Lauren outperformed the consumer durables and apparel sector by 14.6% with 1.55 TEU per million COGS and 16.5% reported Asian revenue exposure, as opposed to Vera Bradley which underperformed by 14.2% with zero reported Asian exposure and 12.41 TEU per million COGS.

Ralph Lauren’s import mix has also changed over the past two years – Panjiva’s data shows seaborne imports linked to the firm fell to 25.4% of the total in 2019 compared to 34.6% in 2018. It’s also worth noting that Vera Bradley delivered fiscal Q4 pre-tax profits that were 33.2% below analysts’ expectations according to S&P Global Market Intelligence figures

Consumer electronics – Sonos vs Garmin

The impact of differentiated supply chains in the consumer durables sector can be seen in the electronics segment. Smart speaker manufacturer Sonos had a 2.87 TEU / COGS ratio and underperformed the sector by 10.6%. Garmin meanwhile only had 0.28 TEU/COGS and outperformed by 14.1%. Sonos also faces the challenge of a high proportion of imports from China at 84.1% of seaborne imports linked to the firm, and as such faces tariffs on most of its imports.

Source: Panjiva

Materials – Ball Corp vs Kraton

Ball Corp and Kraton Corporation are an example in the highly diverse packaging materials sector, with Ball Corporation making jars and packaging, and Karton making synthetic rubbers. Ball Corp. has a relative low exposure to Asia with a TEU / COGS ratio of just 0.02 and an outperformance versus the materials sector of 36.3%. The firm’s performance may have been helped by its focus on aluminum packaging for aerosol systems.

Kraton meanwhile has one of the higher supply chain scores in the sector at 1.82 TEU / COGS, perhaps providing one reason for its 45.2% underperformance. Kraton has specifically indicated that it expects the disruptions caused by COVID-19 to cut demand for its turpentine and tall oil products in 2020 in its recent earnings conference call.

Consumer staples – PriceSmart vs Costco

Costco Wholesale, a retailer in the consumer staples sector, had a import rating of 0.29 TEU / COGS and an asian revenue exposure of 0.09%. This is typical of an American retailer with little business in China. Imports associated with the company from asia fell 10.7% year over year in the three months to Feb 29. Costco performed well year to date, showing sector neutral returns of 16.5%. As flagged in the report above the firm has likely benefited from consumer stockpiling of HPC products.

In contrast, PriceSmart also showed 0.0% revenue exposure to Asia, but had a higher supply chain exposure at 1.43 TEU / COGS. The latter partly explains PriceSmart’s 13.3% stock price decline relative to the consumer staples sector.

Source: Panjiva

Consumer durables – Funko vs Hasbro and Mattel

As discussed already, the toy industry is heavily reliant on China from a supply chain perspective. Funko and Hasbro performed true to that form with sector relative share price declines of 38.9% and 12.5% respectively. Funko had a higher exposure to Asia with 14.3 TEU / COGS compared to Hasbro’s 4.56 TEU / COGS.

Mattel by contrast had a higher exposure than Hasbro with 7.86 TEU / COGS, but overperformed by 10.5%. The latter may reflect excitement about recently announced ventures with Universal Brand (Dreamworks) and Tesla (radio controlled vehicles) rather than ongoing supply chain concerns.

Source: Panjiva

Health care – Glaukos and Orthofix vs Masimo and Penumbra

The health care sector should in theory see a wide range of winners during a global health emergency. Yet, as flagged above, upstream supply shortages can curtail the ability of firms to actually benefit from the trend.

While the healthcare industry covers a wide range of firms from pharmaceuticals to supplies and devices, there are signs of outperformance from firms with low exposure in the U.S. supply chains to Asia. Monitoring systems maker Masimo and surgical access system producer Penumbra outperformed the sector by 23.5% and 19.8% respectively and have minimal exposures to Asia.

By contrast Glaukos and Orthofix underperformed by 24.6% and 15.8% respectively. Glaukos’ had a 0.69 TEU / COGS and a product focus on eye disease that may be de-emphasised in healthcare funding. Orthofix’s ratio was lower at 0.27 TEU / COGS but also has a business – musculoskeletal healing products – that is not directly coronavirus related.

Home & Personal Care – what you sell matters more than where you sell or source it

As hinted at already, what a firm sells may be more important than than any supply chain or revenue considerations. Within the home and personal care sector Edgewell and Clorox, which produce sanitizing products, saw outperformance of 28.8% and 28.2% while luxury goods firms Revlon and Interparfums saw declines of 4.9% and 14.0% respectively. Yet, all four have Asia TEU/COGS of similar magnitudes.

The highest Asia-TEU figure in the HPC group is Spectrum Brands which has a diverse set of products across hardlines and pest control, yet it has performed broadly in line with the sector.

One conclusion, therefore, is that a layering of quantitative and fundamental analysis is needed to fully understand the state of markets at times of significant upheaval.

Source: Panjiva

Appendix – Combining financial and trade data to identify coronavirus exposures – methodology

Panjiva data gives unique insights into companies supply chains – one way to look at this is to take imports from Asia as a proportion of total imports. That shows the proportion of international trade from Asia, but may overestimate the effect on companies that do a relatively small amount of international trade in general.

A more nuanced measure is to measure containerized freight imports (measured in 20-foot equivalent units, or TEUs) from Asia against a neutral measure of a company’s supply chain – in this case cost of goods sold provides a clear scaler across businesses.

The Asian TEU / cost of goods sold metric can be restated as Asian TEU per dollar of goods sold. The metric should be lower for companies that engage in less international trade. For example, a company that imported 10 TEU’s from Asia against a COGS of $100 would receive a score of 0.1 TEU / dollar, as opposed to a company that imported 50 TEU from Asia with the same COGS receiving a score of 0.5 TEU per dollar.

Revenue exposure to Asia is found by taking self-reported geographic revenue segments from S&P Global Market Intelligence’s database and dividing the sum of the Asian revenue segments by total reported revenue. As these numbers are self-reported, not all companies have usable data.

It’s worth noting that it is unlikely that there will be to see companies with high supply chain and high revenue exposure as that would represent either (a) US manufacturers selling in Asia using China components or (b) in-market for-market assembly using globally sourced components. Offshoring trends over the past two decades have made it increasingly unlikely that raw or intermediate goods are produced in the U.S.

Replicating this analysis in Xpressfeed

Finding Asian imports in panjiva data uses the Panjiva U.S. import dataset for 2019. Create a subquery for company resolution from Capital IQ id to Panjiva Id, then join that subquery to panjiva imports. Filter for Asian shipment origins and select wanted fields.

To find revenues, join the Capital IQ segment collection, financial collection, financial instance, financial period, and segment tables together on the below fields. Filter for the data item 3515, geographic segmentation, and the flags for period type, latest period, and form types. Restrict the query to the relevant Capital IQ id, and then filter for various asian countries in the free text descriptions. The filter shown uses a mix of the like operator and exact matches to cover a wide range of options.